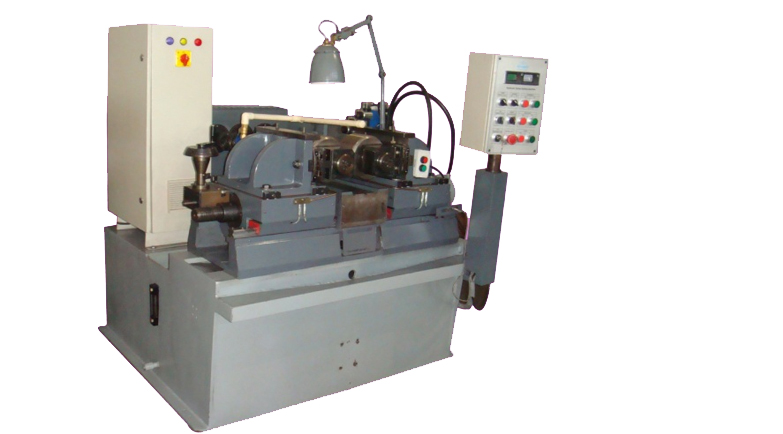

We have developed special 16 ton Thread Rolling Machine with special CNC cycle with multiple sensors and special rolls to roll wiper motor and power windows worms for Lucas TVS.

One of this machines is tooled up to roll ½” 4 TPI ACME screws required for home appliances - hand presses to make Iddiappam / Sev etc.

CNC Rack Rolling Machine can be tooled up to roll masonary drills from the solids and establish tool life more than several lakhs. These drills are brazed with carbide tips to drill concrete walls etc.

Components with threads up to 3.0 mm pitch can be rolled on this machine.