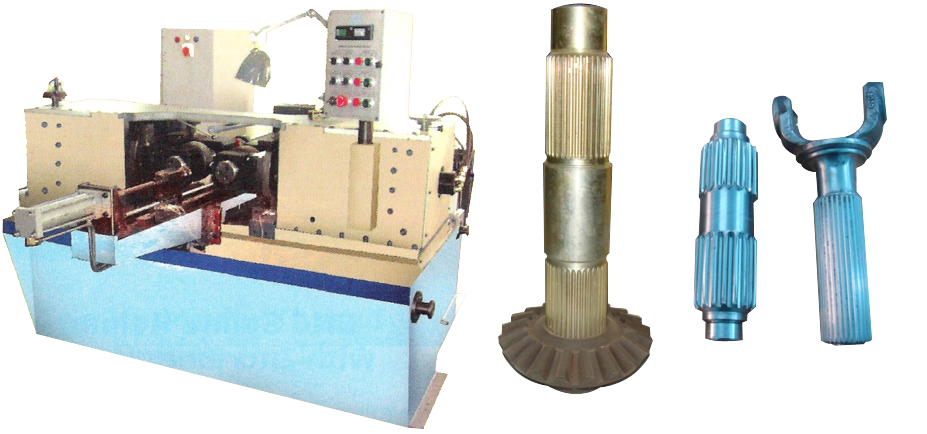

Spline Rolling Machine- great advantage of this machine is that when a component has different number of splines but of same module, all the splines can be rolled in one cycle. One example is Mahindra Nissan main shaft with four splines of different number of teeth, but of the same module.

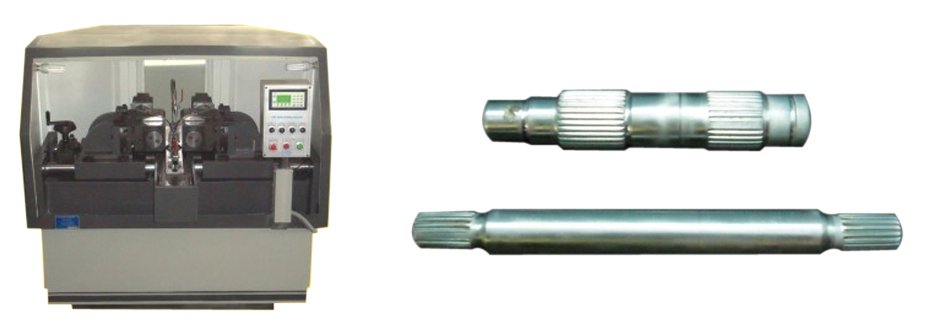

CNC Spline Rolling Machine:

CNC Spline Rolling Machine with Incremental Spline Rolls:

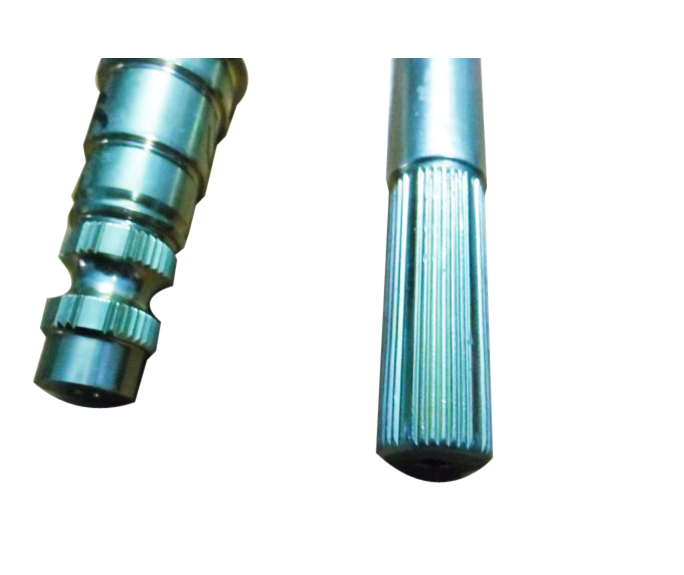

This is an ideal machine for rolling smaller splined components for household appliances, power-steering components with skipped tooth etc. Power windows and wiper motor worms are rolled with special form rolls for modern cars. One component is produced in every rotation of these Incremental Rolls.

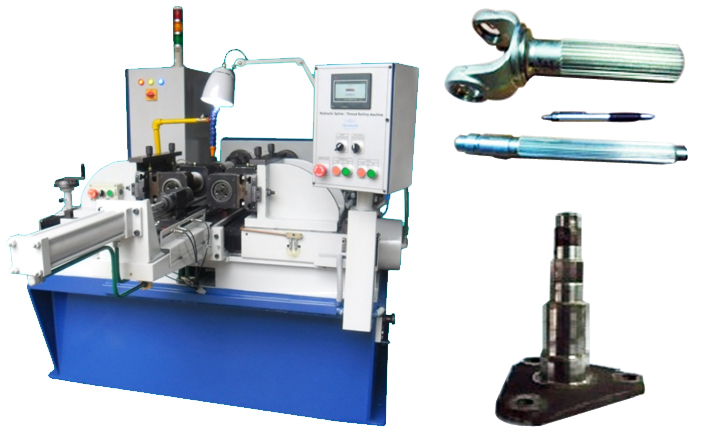

16 Ton Hydraulic Spline Rolling Machine:

16 Ton Spline Rolling Machine is specially designed with linear guide movements to meet most of the normal requirements of spline rolling. One of the components rolled in this 16 Ton Hydraulic Spline Rolling Machine is a stainless steel component with Ø 9.25 x Z 16 x 550 mm long in a single pass required for a dot matrix printer of Wipro make. Components up to 1.00 module can be rolled in this machine.

| Specifications of our 16 ton Hydraulic Spline Rolling Machine | |

|---|---|

| Maximum Roll diameter | 180 mm |

| Bore size | 54 mm std./69.85 mm |

| Max. Roll width | 125 mm |

| Max. Diameter of the job | 50 mm |

| Max. Pitch | 4 mm |

| Max. Spline | 1.00 mod. (higher with helix) |

| Min. Job diameter | 5 mm |

| Max. Spline length | 100 mm std. (higher available) |

| Max. Swing of the Job (Flange Dia) | 100 mm |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 8.5 HP approx.) |

| Floor space | 1.5 x 1.5 meters. |

| Weight of the machine | 2.4 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |

20 Ton Hydraulic Spline Rolling Machine:

Components up to 1.3 module can be rolled in this machine.

| Specifications of our 20 ton Hydraulic Spline Rolling Machine | |

|---|---|

| Maximum Roll diameter | 200 mm |

| Bore size | 54 mm std./69.85 mm |

| Max. Roll width | 125 mm |

| Max. Diameter of the job | 50 mm |

| Max. Pitch | 4 mm |

| Max. Spline | 1.25 mod. (higher with helix) |

| Min. Job diameter | 5 mm |

| Max. Spline length | 100 mm std. (higher available) |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 9.5 HP approx.) |

| Floor space | 1.75 x 1.75 meters. |

| Weight of the machine | 2.6 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |

24 Ton Hydraulic Spline Rolling Machine:

This Spline Rolling Machine with Special Tooling and with HMI is designed for rolling starter motor helical splines with partially skipped tooth form i.e., 12 teeth and 6 teeth for Lucas TVS. Components up to 1.5 module can be rolled on this 24 ton Hydraulic Spline Rolling Machine.

| Specifications of our 24 ton Hydraulic spline Rolling Machine | |

|---|---|

| Maximum Thrust for rolling | 24 ton |

| Maximum Roll diameter | 200 mm |

| Bore size | 54 mm std./69.85 mm |

| Max. Roll width | 125 mm |

| Max. Diameter of the job | 60 mm |

| Max. Pitch | 4 mm |

| Max. spline | 1.5 mod. (higher with helix) |

| Min. Job diameter | 6 mm |

| Max. spline length | 150 mm std. (higher available) |

| Max. Job length | 400 mm between centre |

| Max. Swing of the Job (Flange Dia) | 125 mm |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 12 HP approx |

| Floor space | 1.75 x 1.75 meters. |

| Weight of the machine | 3 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |

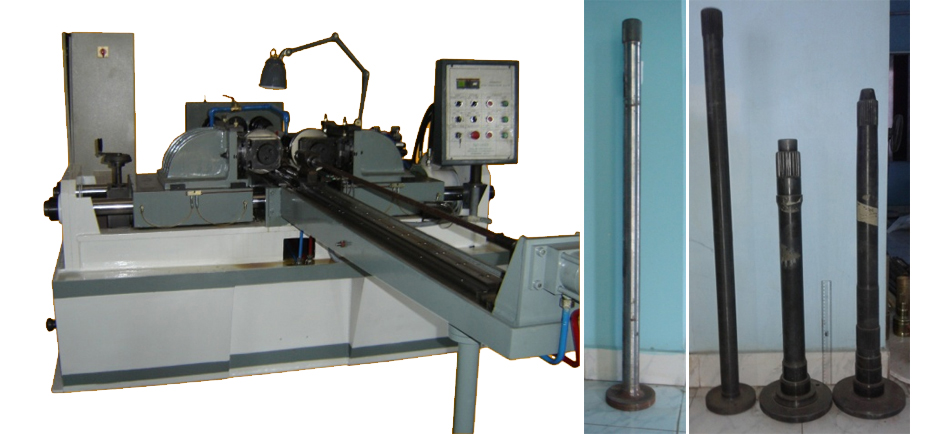

30 Ton Hydraulic Spline Rolling Machine:

Higher capacity Spline Rolling Machine are very popular among our customers to manufacture splined components for automobile transmission and rocker arm for tractors and axle shafts for various trucks and tractor implements.

Our direct and indirect customers are M & M gears, Lucas TVS 3 wheelers division and TAFE, Tractor Implement manufacturers etc.

One of our customers manufactures special axles with high strength material for US drag racing cars. Our machines are used to roll Special stainless steel rollers used for crushing barley for manufacturing homemade beer in USA.

Components up to 1.75 module can be rolled in this machine.

| Specifications of our 30 ton Hydraulic thread Rolling Machine | |

|---|---|

| Maximum Roll diameter | 200 mm |

| Bore size | 69.85 mm |

| Max. Roll width | 130 mm |

| Max. Diameter of the job | 65 mm |

| Max. Pitch | 1.5 module |

| Min. Job diameter | 6 mm |

| Max. spline length | 150 mm std. (higher available) |

| Max. job length | 600 mm between centre |

| Max. Swing of the Job (Flange Dia) | 150 mm |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 14 HP approx |

| Floor space | 2.0 x 2.0 meters. |

| Weight of the machine | 3.5 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |

40 Ton Hydraulic Spline Rolling Machine:

We have developed high capacity (40 ton) Hydraulic Spline Rolling Machine with force feeding system of rolling to roll tractor and truck axles with flange of Ø 150 at one end.

Components up to 2.5 module can be rolled in thisSpline Rolling Machine.

| Specifications of our 40 ton Hydraulic spline Rolling Machine | |

|---|---|

| Maximum Roll diameter | 200 mm |

| Bore size | 69.85 mm |

| Max. Roll width | 130 mm |

| Max. Diameter of the job | 70 mm |

| Max. Pitch | 2.5 module |

| Min. Job diameter | 10 mm |

| Max. Spline length | 150 mm std. (higher available) |

| Max. Job length | 650 mm between centre |

| Max. Swing of the Job (Flange Dia) | 190 mm |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 17 HP approx.) |

| Floor space | 2.5 x 2.5 meters. |

| Weight of the machine | 3.75 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |

60 Ton Hydraulic Spline Rolling Machine:

60 ton Hydraulic Spline Rolling Machinecan roll splines up to 3 module for tractors and truck axles.

Components up to 3.175 module can be rolled in this machine.

| Specifications of our 60 ton Hydraulic spline Rolling Machine | |

|---|---|

| Maximum Roll diameter | 200 mm |

| Bore size | 69.85 mm |

| Max. Roll width | 150 mm |

| Max. Diameter of the job | 76 mm |

| Max. Pitch | 2.5 to 3.175 module |

| Min. Job diameter | 6 mm |

| Max. spline length | 150 mm std. (higher available) |

| Min. job length | 10 mm |

| Max. Spline length | 150 mm std. (higher available) |

| Max. Job length | 650 mm between centre |

| Max. Swing of the Job (Flange Dia) | 150 mm |

| Roll Shaft RPM | Infinitely variable 0-50 RPM std. |

| Gearbox | Hardened and ground helical gears(no worm & worm gears) |

| Lubrication | Centralized lubrication with PLC controls |

| Electrical Control | PLC with 24 Volts DC |

| Slide movement | Both roll shafts move towards center on Imported Linear Guides, hence the job is centrally placed always. |

| Depth/Size control | With positive arrangement |

| Rolling cycle | Spline Rolling –Force Feeding System of rolling, Plunge Rolling Cycle. |

| Connected load (approx.) | 24 HP approx |

| Floor space | 2.5 x 3.0 meters. |

| Weight of the machine | 4.25 tons approx. |

| Construction | Machine grade cast iron body mounted on stress relieved welded body, single piece construction, epoxy coated hydraulic and coolant tank inside the machine. |

| Electricity | The total consumption of electricity will be less on our machine, because of higher efficient gearbox and Variable Speed Drive, for which lower HP motors are used. This will pay back your investment in a short period. |